If you’re working with on-site tech, testing everything is essential. Ready to take a look at some examples, why these things should be tested, and how you can go about doing it?

Valves

Valves are devices that regulate the flow of fluids or gases. They are used in various applications, including plumbing, HVAC, industrial processing, and more. All valves serve the same primary purpose: to control the flow of liquids or gases.

Testing your valves is necessary for two reasons: safety and efficiency. First, valves that do not function properly can pose a safety hazard. For example, a valve that is stuck open may allow too much gas or fluid to pass through, which could lead to an accident or spill.

Second, faulty valves can waste energy and lead to inefficiencies in your business operations. For example, a valve that is stuck closed may prevent the flow of liquid or gas that is needed for a specific process. This can lead to downtime and lost productivity.

There are several ways to do a valve diagnostic test. The most common method is to use a differential pressure gauge. This type of gauge measures the difference in pressure between two points in a system.

To use this method, you will need to attach one side of the gauge to the inlet side of the valve and the other side to the outlet side of the valve. The reading on the gauge will tell you if the valve is open or closed.

Another way to test your valves is with a calibrated ball test kit. This type of kit includes a ball that is slightly smaller than the valve opening. To use this method, you simply insert the ball into the valve opening and observe whether or not it passes through. If the ball passes through, the valve is open; if it does not pass through, it is closed.

Finally, you can also test your valves with an electronic positioner. This device attaches to the actuator on top of the valve. It uses sensors to determine whether or not the valve is open or closed.

No matter which method you choose, it is vital to test your valves—at least once yearly regularly.

Security Systems

There are various types of security systems. As such, the first step in testing your on-site security system is understanding how it works. Familiarize yourself with the different features of your system and how they work together to keep you safe. This will help you when it comes time to test the system and give you a better understanding of how to use the system in an emergency situation.

You should test your on-site security system regularly, at least once a month, if not more often. This will help ensure that there are no weak points that could be exploited by an attacker.

When you’re testing your on-site security system, be thorough. This means not only testing the physical components of your system but also testing the digital aspects.

For example, if you have a CCTV system, test both the cameras and the recording equipment to ensure that they’re working correctly. If you have an alarm system, test all of the sensors as well as the control panel to make sure that they’re triggering correctly. Taking the time to do a thorough test will help you feel confident that your system is up to par and ready to protect you in an emergency situation.

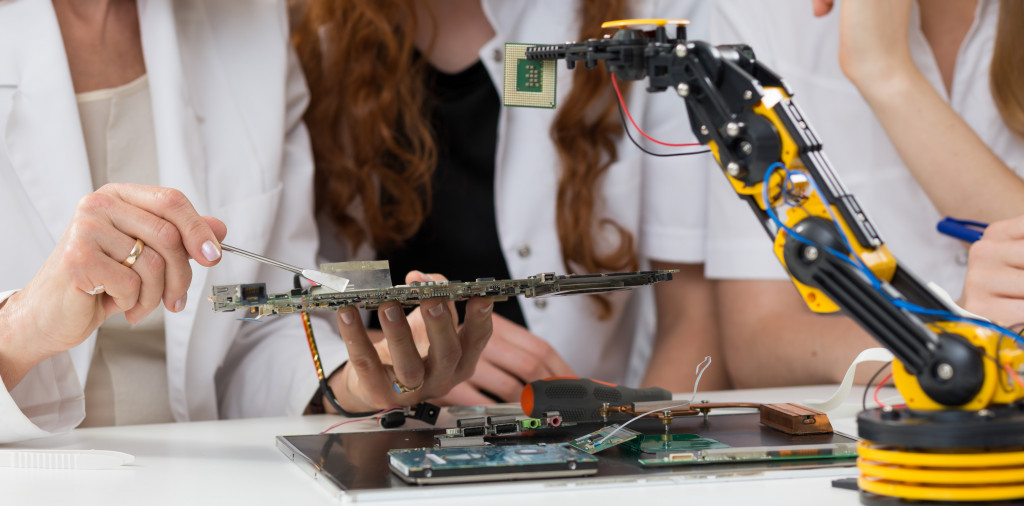

Robots

Testing robots are an integral part of ensuring their quality and performance. Before doing this, ensure you define the scope of the test. What do you want to learn from the test? What are your goals? Answering these questions will help you determine which tests to run and how to interpret the results.

Also, choose the right environment. The environment in which you test your robot is important. For example, if you’re testing a domestic robot, you’ll want to use a home environment rather than a laboratory setting. This will help ensure that the results of the test are representative of real-world conditions.

Finally, be realistic about what the robot can achieve. Otherwise, you’ll be disappointed with the results of the test. Remember that robots are still machines, and they are subject to the same limitations as any other machine.

It’s always necessary to test on-site tech before and after using it. This is especially true for things like valves, robots, and security systems. By testing these things ahead of time, you can avoid potential problems down the road. So, don’t forget to put everything through its paces regularly.